Innovative Additive Solutions: iGM Resins Expands Its Omnivadd® Range

iGM Resins: A Leader in Energy-Curing Technologies

iGM Resins is a global specialist in the development, manufacture, and supply of energy-curing raw materials, serving the coatings and inks industries. The company’s product portfolio is built on three key pillars: photoinitiators, energy-curing resins, and additives. These solutions support formulators in achieving high-performance, sustainable, and efficient energy-curable coatings and inks, ensuring superior quality and durability.

As a key player in the radiation-curing industry, iGM Resins continuously innovates to meet evolving market demands. Recently, the company has strengthened its additives portfolio, rebranding the Omnistab additives to the new Omnivadd® brand and introducing a range of high-performance solutions designed to enhance formulation stability, durability, and appearance.

A Closer Look at the Newly Added Omnivadd® Additives

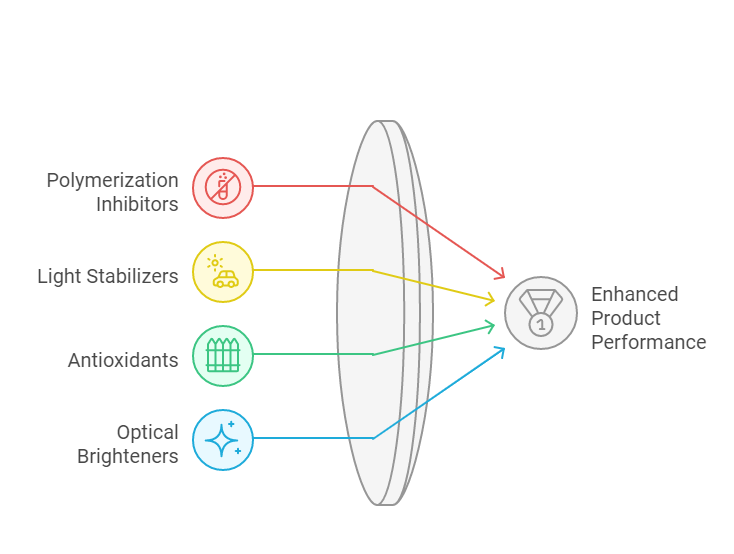

Additives play a crucial role in coatings and inks, influencing properties such as UV stability, adhesion, gloss, and polymerization control. The Omnivadd® range comprises polymerization inhibitors, light stabilizers, antioxidants, and optical brighteners, offering formulators advanced tools to optimize their products.

- Polymerization Inhibitors: Branded under the Omnivadd® IN series, these additives help extend shelf life by preventing unwanted polymerization during storage and processing. They work by scavenging free radicals and slowing down premature cross-linking, ensuring that formulations remain stable and easy to apply.

- Light Stabilizers: Branded under the Omnivadd® LS series, these compounds protect coatings from UV-induced degradation, preventing discoloration, chalking, and surface deterioration. By absorbing and dissipating UV radiation, they extend the longevity and aesthetic quality of coatings used in automotive, wood, and industrial applications.

- Antioxidants: Branded under the Omnivadd® AN series, these additives prevent thermal and oxidative degradation, enhancing the stability of coatings, adhesives, and plastics. They neutralize peroxides and free radicals generated during high-temperature processing, reducing material breakdown and extending product lifespan.

- Optical Brighteners: Branded under the Omnivadd OB series, these fluorescent whitening agents enhance brightness and whiteness in paper, coatings, and inks. They provide a brilliant bluish effect by absorbing ultraviolet light and emitting visible blue light, improving contrast and visual appeal while ensuring high chemical stability for long-lasting performance.

Introducing the Newest Additions to the Omnivadd® Line

To further enhance its offerings, iGM Resins has introduced several new Omnivadd® additives to meet emerging industry needs. Among them:

- Omnivadd® LS 400:

A next-generation UV absorber based on hydroxyphenyl-triazine (HPT) technology, offering outstanding durability, resistance to high temperatures, and compatibility with multiple coating systems, making it ideal for automotive OEM, industrial, and coil coatings. - Omnivadd® LS 928:

A high-performance benzotriazole UV absorber, tailored for wood, powder, and coil coatings, ensuring long-term color stability, protection against yellowing, and enhanced weather resistance. - Omnivadd® AN 1010 & AN 168:

Newly launched antioxidants designed to enhance polymer stability, particularly in polyolefin, polyurethane, and elastomeric applications. They function by inhibiting oxidation during processing and end-use, thereby prolonging product lifespan. - Omnivadd® IN 535:

A high-efficiency polymerization inhibitor, specifically developed to extend the shelf life of metallic UV coatings and inks by preventing premature polymerization in heat-sensitive formulations. - Omnivadd® OB:

A powerful optical brightener that enhances whiteness and contrast in coatings, printing inks, and plastic applications. It works by converting invisible UV light into visible blue light, improving perceived brightness and clarity while maintaining excellent heat and chemical resistance. Additionally, it offers strong performance in both solvent-based and water-based formulations, making it a versatile solution for multiple industries.

The Full Omnivadd® Additives Portfolio

In addition to the newly added Omnivadd® products, iGM Resins offers a broad range of existing additives that enhance coating and ink formulations. These include:

- Binders for Pigment Concentrates:

Essential for dispersing and stabilizing pigments, ensuring uniform coloration and enhanced compatibility with various resin systems. - Foam Control Additives:

Designed to prevent and eliminate foam formation in coatings and inks, ensuring smooth application and optimal film formation. - Slip & Leveling Agents:

Improve surface smoothness, reduce defects, and enhance flow properties, leading to high-quality, uniform coatings. - High and Low Molecular Weight Dispersants:

Optimize pigment dispersion, enhance color strength, and prevent settling, ensuring long-term stability of formulations. - Bio-Based Solution - PureVadd®:

A sustainable additive that enhances the performance of energy-curable systems while reducing environmental impact.

Innovation for the Future

iGM Resins continues to push the boundaries of innovation with its Omnivadd® additives, ensuring formulators have the best tools to enhance stability, performance, and longevity in coatings and inks. By expanding its range with cutting-edge UV absorbers, antioxidants, and polymerization inhibitors, iGM Resins reaffirms its commitment to quality, sustainability, and performance.

With these new products, the company not only strengthens its leadership in energy-curing technologies but also empowers formulators with superior solutions to tackle the industry’s most pressing challenges.