Photomer® 4357: A brand new and improved liquid version of THEICTA

As a global leader in the radiation curing market, iGM Resins, remains increasingly committed to driving innovation. This dedication is shown by the recent launch of Photomer® 4357, an advanced and enhanced evolution of THEICTA (also known as Photomer® 4356).

Photomer® 4357 is a high-performance specialty acrylate monomer, specifically engineered to address the evolving demands of the energy curing industry.

With its unique chemical structure and exceptional properties, this versatile material is ideally suited for a wide range of applications, including graphic arts, industrial coatings, adhesives, and 3D printing.

Photomer® 4357 technical data

Appearance: Clear liquid

Viscosity (25°C, cps): 2,000 ~ 4,000

Tg (°C) ≈ 195 ~ 200

Refractive index: 1.5012

Purity (GC, %): 97.5 - 98.5

Comparison Between Photomer® 4356 (THEICTA) and Photomer® 4357

Photomer® 4356 and Photomer® 4357 are two specialty acrylates within the Photomer® range, designed to cater to the needs of energy curing applications. While they share several core properties, critical differences in their physical forms and performance characteristics allow formulators to choose the most suitable product based on application requirements.

1. Shared Properties

Both Photomer® 4356 and Photomer® 4357 exhibit key qualities that make them reliable choices for high-performance formulations.

- High Reactivity: Both products cure efficiently under UV or EB light, enabling fast processing and reduced cycle times.

- Excellent Adhesion: Both demonstrate strong adhesion to a wide range of substrates, including plastics, metals, and glass.

- Durable Performance: Both deliver good mechanical properties, including hardness and abrasion resistance, for long-lasting coatings

- Comparable Glass Transition (Tg): The Tg of both products is similar, ensuring consistent thermal performance in applications requiring stability.

Photomer® 4356 is the acrylate with the highest Tg in the UV portfolio (above 250°C), making it highly valuable for formulating UV systems that require resistance to high temperatures or for fine-tuning the Tg of specific systems. Photomer® 4357, with a lower Tg (around 150°C), still offers an exceptionally high Tg for UV-curing acrylates, making it equally useful for similar requirements.

2. Key Differences

Physical Form and Handling:

Photomer® 4356 (THEICTA): A wax-like solid that may require additional steps for handling, such as melting or premixing. This characteristic can be beneficial in applications where solid-state materials are preferred.

Photomer® 4356 (THEICTA): A wax-like solid that may require additional steps for handling, such as melting or premixing. This characteristic can be beneficial in applications where solid-state materials are preferred.

Photomer® 4357: A liquid, making it easier to incorporate into formulations without the need for pre-processing. Its liquid form ensures enhanced compatibility with other liquid components in a system.

Elongation: Photomer® 4357 offers higher elongation than Photomer® 4356, making it a better choice for applications requiring flexibility, such as 3D printing or flexible coatings.

Photomer® 4357 is a larger molecule, and in comparative tests, it delivers virtually the same tensile strength and modulus as Photomer® 4356. With its higher elongation, Photomer® 4357 is particularly suited for high-impact-resistant coatings used in automotive applications and is especially valuable for tough materials in additive manufacturing.

Re-Crystallization:

Photomer® 4356 (THEICTA) is prone to re-crystallization over time, which can affect storage stability and ease of use in formulations. Photomer® 4357, on the other hand, is highly stable and does not exhibit re-crystallization, ensuring a longer shelf life and greater formulation reliability.

3. Application Suitability

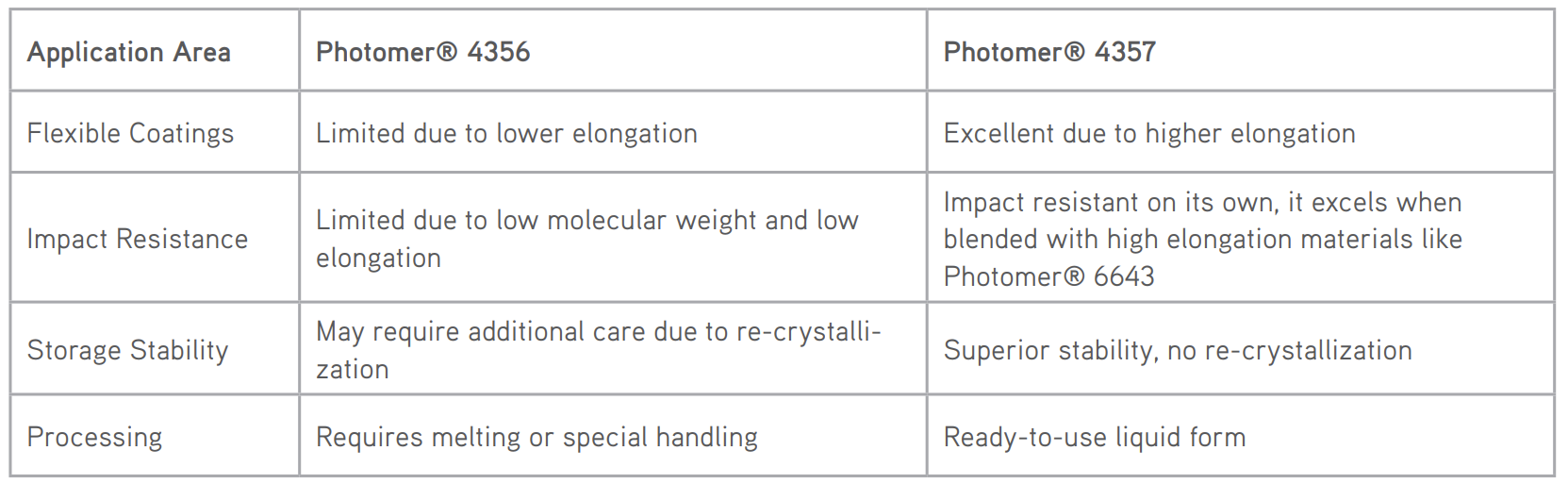

The differences between Photomer® 4356 and Photomer® 4357 influence their suitability for specific applications:

Applications

Photomer® 4357 is specifically engineered to enhance performance across diverse applications:

- Graphic Arts: Its high reactivity and clarity make it suitable for inks and varnishes, delivering sharp, vibrant results.

- Industrial Coatings: Provides robust chemical and mechanical resistance for protective coatings on metals, wood, and plastics.

- Adhesives: Ensures strong, durable bonds in high-performance adhesive formulations.

- 3D Printing: The enhanced mechanical properties and very low viscosity make it ideal for 3D printing technologies based on VAT polymerization and inkjet.

Why Choose Photomer® 4357?

iGM Resins, as a global leader in energy curing raw material solutions, ensures Photomer® 4357 meets the highest standards of quality and consistency. This product is supported by our dedicated technical application team, providing tailored guidance for your formulation needs.

Whether you’re developing cutting-edge coatings, innovative adhesives, or advanced 3D printing materials, Photomer® 4357 is a reliable solution designed to enhance performance, sustainability, and efficiency in energy curing applications.

For further details or technical support, please contact iGM Resins. Product Data Sheet (PDS) and Safety Data Sheets (SDS) can be downloaded from our website or obtained by reaching out to us directly.